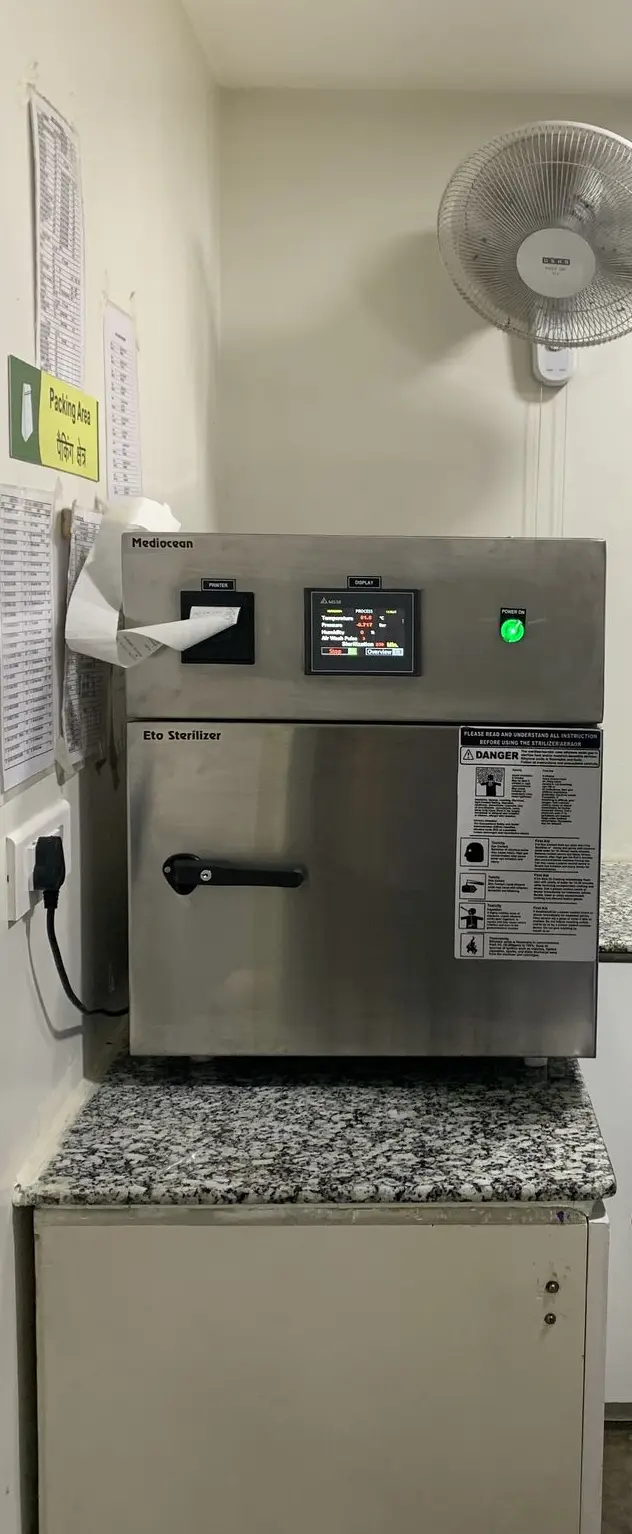

ETO STERILIZER

Mediocean ETO sterilizers offer a comprehensive solution to address concerns related to microorganisms and their risks. These compact and versatile sterilizers are meticulously designed using professional analytical methods tailored to user needs. Combining superior quality and unmatched reliability, they ensure minimal hassle and maintenance. What truly sets them apart is their user-friendly design, making the sterilization process seamless. Mediocean ETO sterilizers are specifically crafted to deliver safe and efficient sterilization for hospitals, laboratories, and research centers.

Quiet and Efficient Operation

Operates with low noise and exceptional vacuum potential for a seamless experience

Precise Control and Performance

Ensures accurate temperature and pressure detection with consistent heating across the chamber

Advanced Functionality

Includes systematic programs and an inbuilt humidity generator for optimal performance

Data Management

Supports USB and printer compatibility for reliable data backup and record-keeping

Unveiling Innovation with Intelligent Design and Advanced Features

Ergonomic and Intuitive Touch Display

High-resolution, user-friendly touch screen with clear visibility and intuitive navigation.

Smart Alerts and Remote Access

Automatic error alerts, optional eRemote for Wi-Fi monitoring, and eServer for seamless data transfer.

Energy Efficiency

Low-temperature process reduces energy consumption compared to traditional methods.

Data and Compliance

Integrated printer for cycle documentation and optional 21 CFR Part 11 compliance for regulatory standards.

Built-in Safety and Backup

Inbuilt compressor, auto process resume, and overheat protection for uninterrupted and safe operations.

Oil-Free System

Spark-free, reliable operation with enhanced safety and low maintenance.

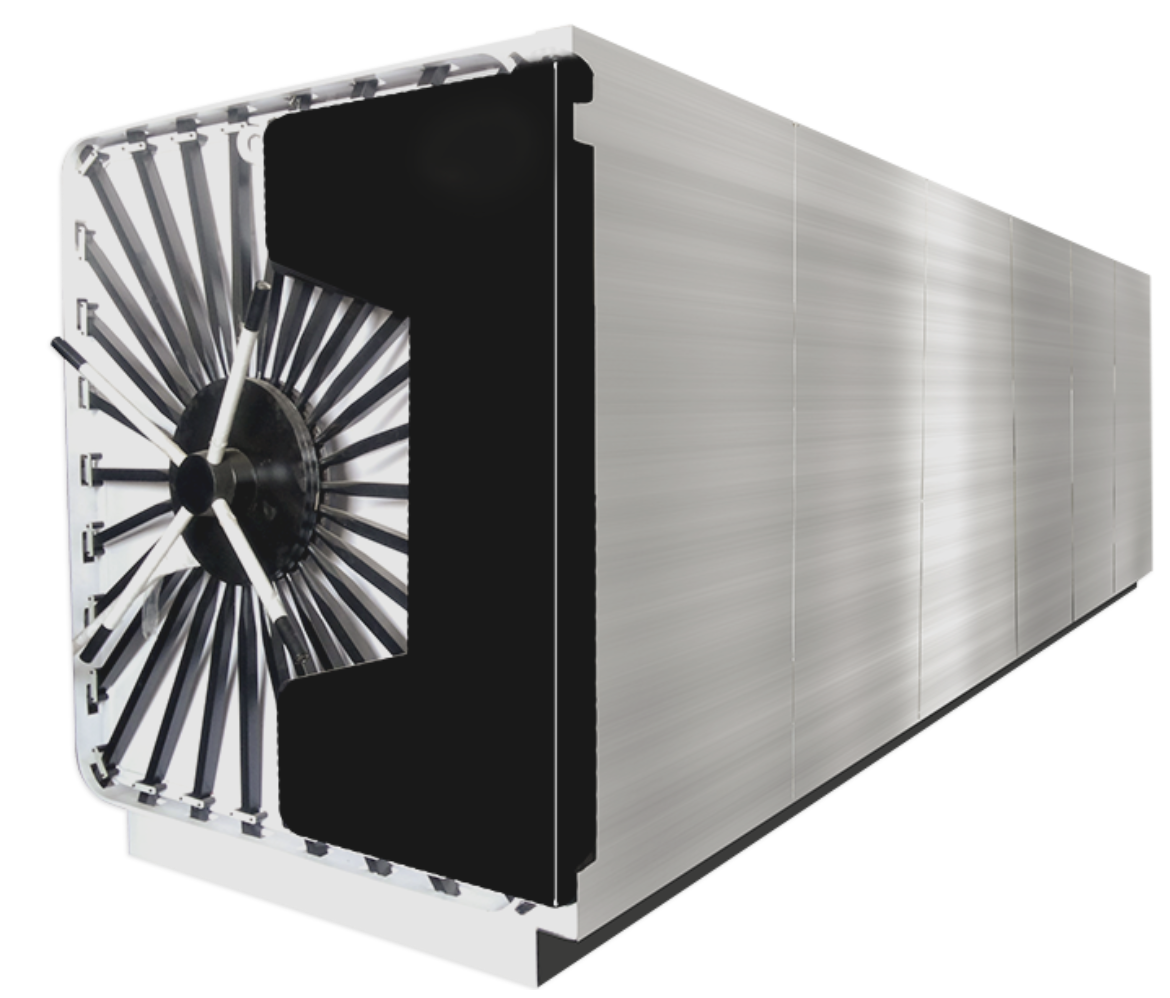

| Model | Chamber Size (Ft) |

|---|

| SterI 1.2 | 3.0Ft x 3.0Ft x 5.0Ft |

| SterI 3.6 | 4.0Ft x 4.0Ft x 8.0Ft |

| SterI 7.0 | 5.0Ft x 5.0Ft x 10.0Ft |

| SterI 10.0 | 5.0Ft x 5.0Ft x 15.0Ft |

| SterI 20.0 | 6.0Ft x 6.0Ft x 20.0Ft |

Key Elements

- Precise Temperature & Pressure Control: Ensures accurate detection and regulation.

- Systemized Programs: Equipped with adequate, organized programs for efficient operation.

- Low Noise & Exceptional Vacuum Potential: Minimizes noise pollution while maintaining superior vacuum performance.

- Uniform Heating: Provides consistent heating throughout the chamber for effective sterilization.

Additional Services

- Design Qualification Reports (DQ): Ensuring the design meets required standards.

- Installation Qualification Reports (IQ): Verifying proper installation according to specifications.

- Operating Qualification Reports (OQ): Confirming that the system operates correctly within the specified parameters.

**We are dedicated to more than just providing equipment. We assist with project planning, ensuring the right specifications and requirements are met. With extensive experience in manufacturing, installation, and commissioning, we manage the entire project from start to finish. Once operational, our proactive maintenance ensures maximum uptime and reliability.